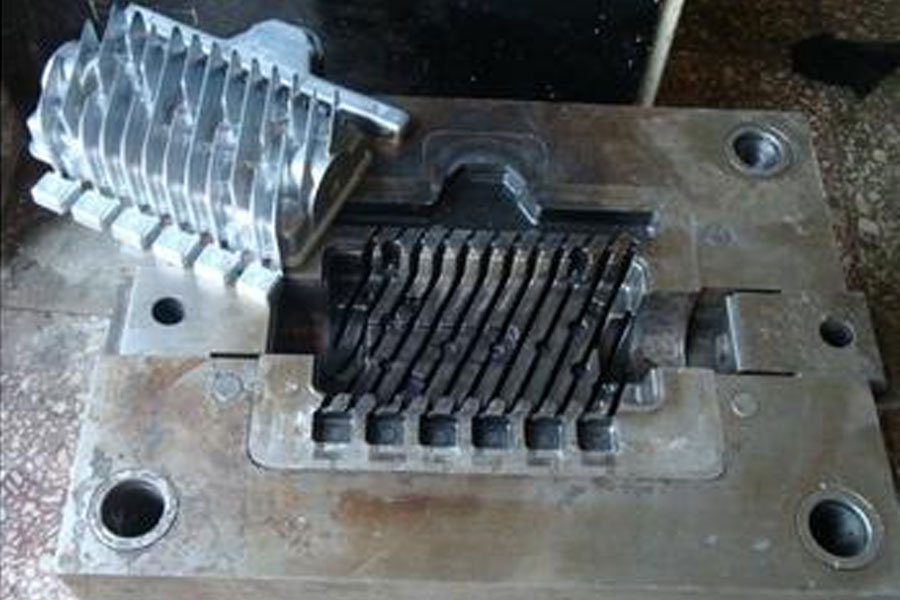

Injection moldIt is a tool for producing plastic products; it is also a tool for giving plastic products a complete structure and precise dimensions.Mainly used in the industrial field, the pouring system of the injection mold is also called the runner system. It is a set of feed channels that lead the plastic melt from the nozzle of the injection machine to the cavity. Material cavity composition.It is directly related to the molding quality and production efficiency of plastic products.

Main road

It is a passage in the mold that connects the nozzle of the injection molding machine to the runner or cavity.The top of the main runner is concave in order to connect with the nozzle.The diameter of the main runner inlet should be slightly larger than the nozzle diameter (8mm) to avoid overflow and prevent the two from being blocked due to inaccurate connection.The diameter of the inlet depends on the size of the product, generally 4-8mm.The diameter of the main runner should be expanded inward at an angle of 3° to 5° to facilitate the demolding of the runner.

Gate

The gate is also called the feed port. It is the narrow opening between the runner and the mold cavity, and it is also the shortest and thinner part.Its function is to use the shrinkage of the flow surface to accelerate the plastic. The high shear rate can make the plastic good fluidity (due to the shear thinning characteristics of the plastic); the heating effect of the viscous heating also increases the material temperature and reduces the viscosity. effect. ?

After the molding is completed, the gate is the first to be cured and sealed to prevent the plastic from reflowing, and to prevent the pressure of the cavity from falling too fast, which causes the molded product to shrink and dent.After forming, it is convenient to cut off to separate the runner system and plastic parts.

Cold feed hole

It is a cavity at the end of the main runner to trap the cold material generated between two injections at the end of the nozzle to prevent the clogging of the runner or gate.Once the cold material is mixed into the cavity, internal stress is likely to occur in the manufactured product.The diameter of the cold material cavity is about 8-6mm, and the depth is XNUMXmm.In order to facilitate demolding, the bottom is often borne by the demolding rod.The top of the stripping rod should be designed in a zigzag hook shape or set with a recessed groove, so that the sprue can be pulled out smoothly during demolding.

Shunt

It is the channel connecting the main channel and each cavity in the multi-slot mold.In order to make the melt fill the cavities at the same speed, the arrangement of the runners on the mold should be symmetrical and equidistant.The shape and size of the cross-section of the runner have an impact on the flow of the plastic melt, the demoulding of the product and the difficulty of mold manufacturing.If the flow of the same amount of material is used, the flow channel resistance with a circular cross-section is the smallest.However, because the specific surface of the cylindrical runner is small, it is unfavorable for the cooling of the runner redundant, and the runner must be opened on the two mold halves, which is laborious and easy to align.Therefore, trapezoidal or semicircular cross-section runners are often used, and they are opened on half of the mold with a stripping rod.The runner surface must be polished to reduce flow resistance and provide a faster filling speed.The size of the runner depends on the type of plastic, the size and thickness of the product.For most thermoplastics, the cross-section width of the runners does not exceed 8m, the extra-large ones can reach 10-12m, and the extra-small ones are 2-3m.On the premise of meeting the needs, the cross-sectional area should be reduced as much as possible, so as to avoid adding debris in the runner and prolonging the cooling time.

Basic principles of gating system design

1. Consideration of Cavity Layout

1) Try to use Balances Layout;

2) The layout of the mold cavity and the gate opening should be symmetrical to prevent the uneven load of the mold from being unevenly loaded, and the problem of mold flashing;

3) The cavity layout is as compact as possible to reduce the size of the mold.

2. Flow guidance considerations

1) It can smoothly guide the molten plastic to fill the mold cavity without generating eddy currents, and can smoothly exhaust;

2) Try to avoid the impact of the plastic melt on the core and metal inserts with a smaller diameter to prevent core shift or deformation.

3. Consideration of heat loss and pressure drop

1) The smaller the heat loss and pressure drop, the better;

2) The process should be short;

3) The cross-sectional area of the runner should be large enough;

4) Try to avoid the bend of the runner and sudden change of flow direction (change the direction at an arc angle);

5) The surface roughness should be low during runner processing;

6) Multi-point pouring can reduce the pressure drop and the required injection pressure, but there will be suture problems.

4. Consideration of flow balance

1) When filling a mold with multi-cavity (Multi-Cavity), the flow channel should be balanced, and try to make the plastic fill each cavity at the same time to ensure the quality consistency of the molded products of each cavity;

2) Try to use the natural-balanced layout of the runners (Naturally-Balanced Layout);

3) When the natural balance is not possible, the artificial balance method is used to balance the flow channel.

5. Scrap considerations

Under the premise of smooth filling without affecting the flow and pressure loss, reduce the flow channel volume (length or cross-sectional area) to reduce the waste production and recycling costs of the flow channel.

6. Cold material considerations

Appropriate cold slug wells and overflow troughs are designed on the runner system to supplement the colder plastic wave front at the initial stage of filling and prevent the cold material from directly entering the mold cavity and affecting the filling quality.

7. Exhaust considerations

The plastic should be smoothly guided to fill the mold cavity and allow the air in the mold cavity to escape smoothly to avoid the problem of scorching of the encapsulation.

8. Consideration of the quality of molded products

1) Avoid short shots, burrs, encapsulation, suture lines, flow marks, jets, residual stress, warpage deformation, mold core deviation and other problems;

2) When the runner system has a long process or multiple gating (Multiple Gating), the warpage and deformation of the finished product caused by unbalanced flow, insufficient pressure or uneven shrinkage should be prevented;

3) The appearance of the product is good, it is convenient to remove and trim the gate, and the gate mark (Gate Mark) does not damage the appearance and application of the plastic part.

9. Consideration of production efficiency

Minimize the required post-processing, shorten the forming cycle and improve production efficiency.

10. Consideration of ejection point

It is necessary to consider the proper ejection position to avoid the deformation of the molded product.

11. Considerations for using plastics

For plastics with higher viscosity or shorter L/t, avoid using too long or too small runners.

A set of high-quality molds requires not only good processing equipment and skilled mold manufacturing workers, but also a very important factor is to have a good mold design. Especially for complex molds, the quality of the mold design accounts for 80% of the mold quality. %above.An excellent mold design is: on the premise of meeting the requirements of customers, the processing cost is low, the processing difficulty is small, and the processing time is short.To achieve this, it is necessary not only to fully digest the requirements of customers, but also to the injection molding machine, mold structure, processing technology andInjection moldingMould factorySome understanding of its own processing capabilities.

Link to this article:How to design the injection mold gating system?