What details can be used to allow injection mold manufacturers to reduce mold repairs

Generally, an injection mold has a planned life of 300,000 times, and 50,000 times requires a major maintenance. In the production cycle, except for the wearing parts of the spring thimble and apron, other parts do not need to be replaced. But in fact, molds are repaired and repaired, and even a set of mass-produced molds will be repaired 2-3 times a month.

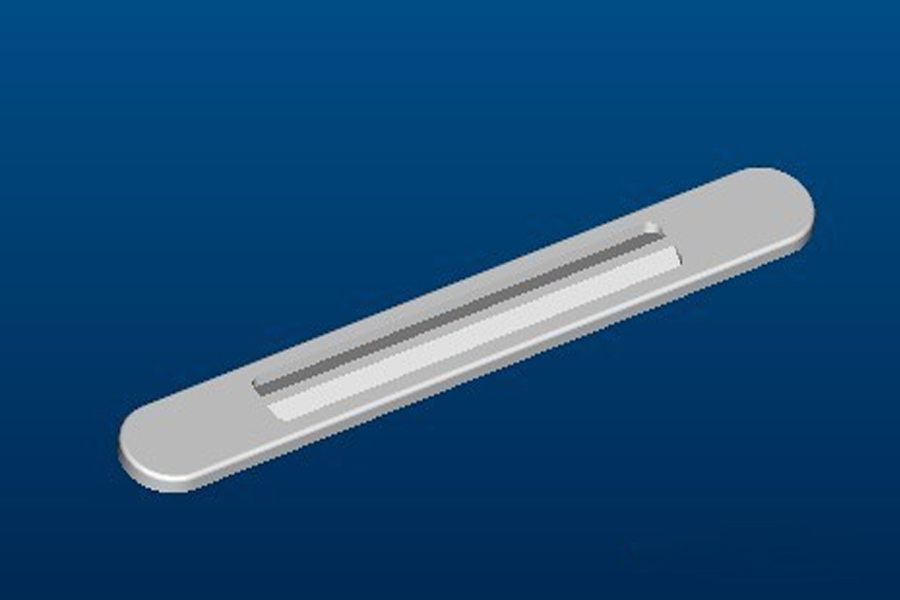

Therefore, in the use of tens of thousands of injection molds, it is inevitable that the mold will be damaged and repaired. As long as we find a way to shorten the repairing time, the production efficiency and cost of the injection mold manufacturer will be improved. The following picture is an example to explain how to make injection mold manufacturers reduce mold repairs! Production control. In the similar table, the hot runner block iron and PIN pin stuck to the mold should be prevented as much as possible.

Injection mold maintenance. The primary and secondary maintenance in normal production and the tertiary maintenance of the mold repair part should be thick and in place, any wire drawing dust should be prevented, and the tension spring break/thimble stuck/shovel chicken stab and so on must be prevented. Standardization of operating procedures, personnel training and performance appraisal. Strengthen the training of scientific injection common sense, try not to damage the mold during production.

Incorrect parameters such as low pressure maintenance settings, mold clamping speed, clamping force, injection speed, holding pressure, mold temperature, etc. will greatly damage the mold, which must be paid attention to. The shortcomings in the tire should be prevented. The mold planning and production process is “pregnancy”. At this time, there must be no shortcomings, or repairs cannot be prevented. For example, the planning and raw materials of the 7 major systems of molds. Standardization and inventory of wearing parts. The thimble/tension spring/siphon/guide post/guide sleeve should be as consistent as possible and keep in stock.