Three common polishing methods for precision stamping molds in precision mold factories

There are two main purposes of polishing precision stamping molds. One is to increase the brightness and appearance of precision molds. The second is to make the mold easy to demold. When polishing, rough oilstone is generally used to rough sand the surface of the machined mold cavity, and the knife marks of the machine tool are polished, and then fine oilstone is used to polish to remove the rough oilstone to reach the traces, and then use the finer Sandpaper polishes the polished surface of the fine oilstone, and finally uses polishing paste or abrasive paste to polish the surface of the mold cavity, and finally achieves a mirror-like effect.

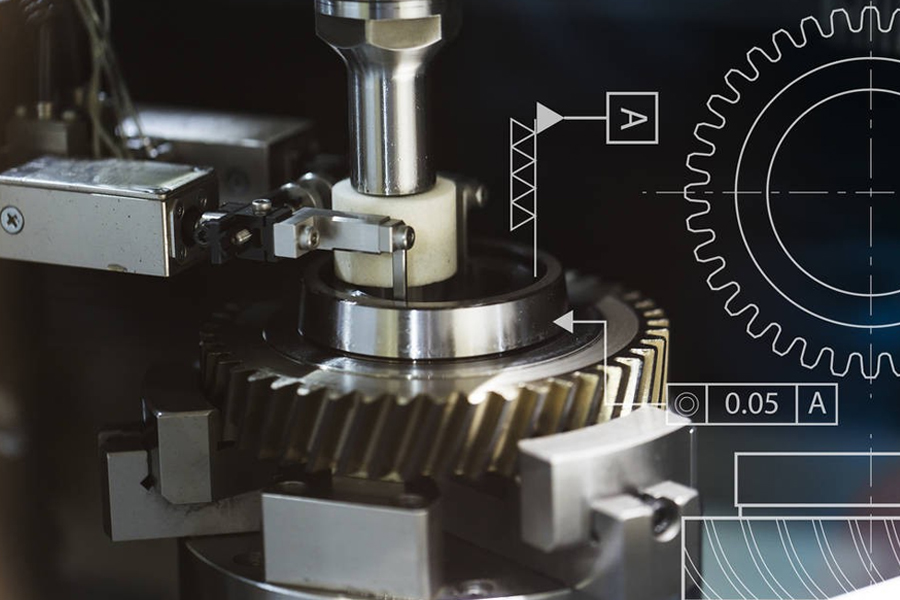

1. Mechanical polishing: The mechanical polishing of precision stamping molds is a polishing method that relies on cutting and plastic deformation of the material surface to remove the polished convex parts to obtain a smooth surface. Generally, oil stone sticks, wool wheels, sandpaper, etc. are used, and manual operations are the main ones. For special parts such as the surface of a rotating body, auxiliary tools such as turntables can be used, and ultra-precision polishing can be used for high surface quality requirements. Ultra-precision polishing is the use of special abrasive tools, which are pressed against the processed surface of the workpiece in a polishing liquid containing abrasives for high-speed rotation. The surface roughness of Ra0.008μm can be achieved by this technology, which is very high among various polishing methods. Optical lens molds often use this method.