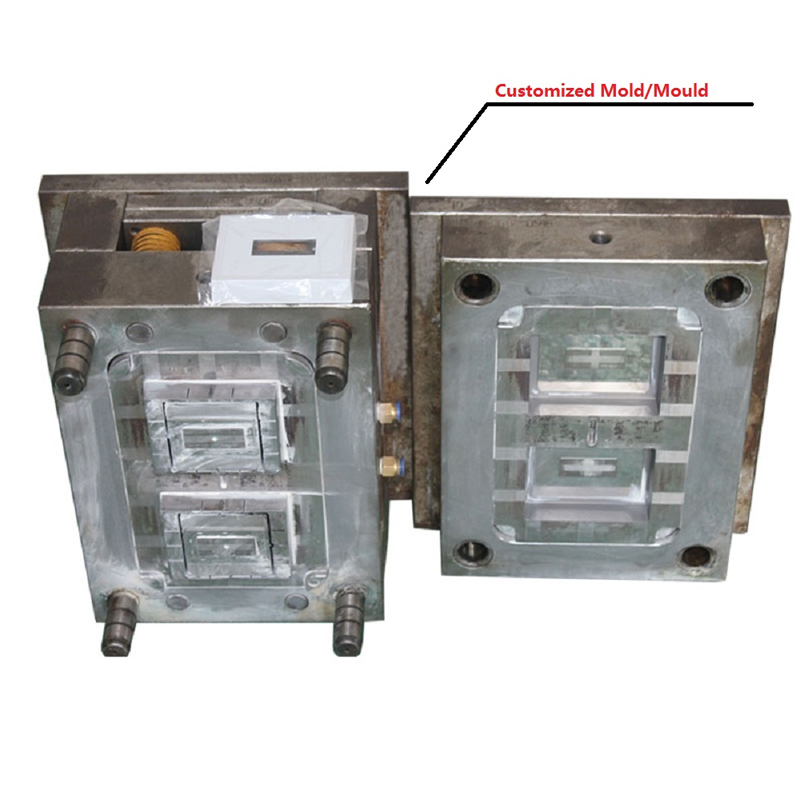

Latest design molding plastic injection mould/plastic mold/plastic injection manufacturers custom service

Our services are including:

- 1. Product design and development, both ODM and OEM.

- 2. Scanning data. (Get 3D drawing per your delivered sample)

- 3. Drawing re-construction. (Simple design is free of charge)

- 4. Prototype making. (It is optional and we will charge the cost.)

- 5. Tooling/Mold setup and trial shot.

- 6. Injection molding for the plastic parts.

- 7. Mass production. (price will be very cheap with large quantity)

| Product name | Latest design molding plastic injection mould/plastic mold/plastic injection manufacturers custom service |

| Products Variety | We design and manufacture plastic injection molds auto parts, home applications,

medical products, Household commodities, consumer electronics, mobile phone parts and accessories, and many other kinds of molds in different fields. |

| Main services | 3D design, Prototypes, Mold design, Mold making, Mold tesing,

Low volume/ High volume plastic injection production |

| Design Software | UG,Pro E Solidwork,AutoCAD,Moldflow…. |

| Core&Cavity Material | P20,H718,S136,SKD61,2738,DC53,H13…. |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mould Cavity | Singe or multi cavity |

| Mold strandard parts | DME, HASCO, etc. |

| Runner | Hot runner, Cold runner |

| Hot Runner Brand | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc |

| Mold cold runner | Side gate,Sub gate,Pin point Gate… |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| plastic Injection Machine | 10sets,110T,140T,160T, 200T,260T,320T |

| Plastic Material | PP,Pa6,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| MOQ | 1set for mold ,plastic products as per your request |

| Mold Life | 300000-500000 shots as per customers’ requirement |

| Inspection | As customers’ requirements |

| Delivery | Air cargo, Sea shipping |

| Lead time | 25-35days for mold,plastic products according to quantity |

Wonder is founded in 1995, with around 30 years experience. We are mainly engaged in R&D mold and product design,molding, plastic injection parts and assembling, covering various fields, covering automotive, electronics,medical, industry and toy parts.

For production, we have inhouse facility to process CNC, milling, grinding, EDM, Wire-cut, as well as injection molding.

Our company is positioned in the middle and high end market in order to guarantee the high precision requirements.We have strict quality team to make sure what our customers received are the best molding products for their new products.

Why choose us?

- 1. Reliable offshore mould and molding manufacturer.

- 2. Both injection mould making and plastic parts producing.

- 3. Own custom research and develop department.with 30+years’ experience in mould industry,high-skilled engineers, toolmakers and inspectors handle project in every steps.

What is beneficial for you?

- 1. Free quotation for your comparison.

- 2. Design mould with price priority, easily processing and quality assurance.

- 3. Get a strategic long-term partner.

- 4. Get the best service.

What should be provided to get price?

Samples , pictures with dimension , drawings and specific requirements.

How to contact us?

Send your inquiry details in the Below. Click “Send” Now!

Warmly welcome you come and visit our factory in Dongguan China.