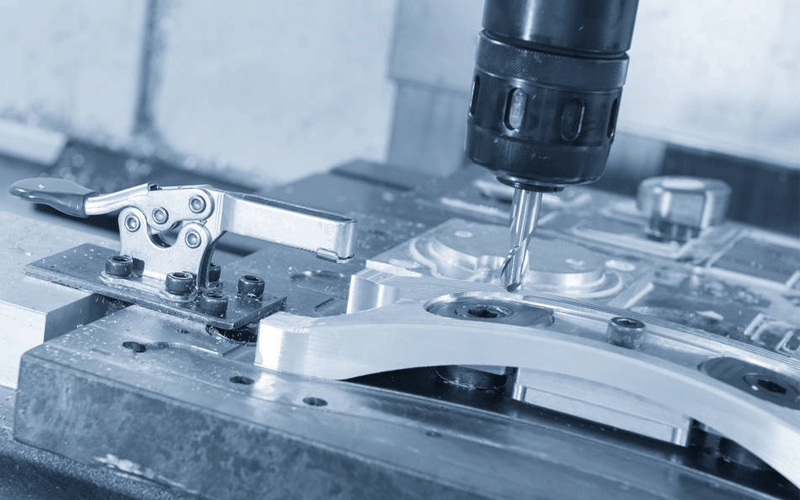

Injection moldThere are six major systems, and the guiding system is set up to ensure that the movable mold and the fixed mold can be accurately centered when the mold is closed, and the guiding component must be set in the mold.In the injection mold, four sets of guide posts and guide sleeves are usually used to form the guide part. Sometimes, it is necessary to set the inner and outer conical surfaces that coincide with each other on the movable mold and the fixed mold to assist in positioning.

The guide post mainly plays a guiding role in the mold to ensure that the molding surfaces of the core and the cavity do not collide with each other under any circumstances. The guide post cannot be used as a force-bearing part or a positioning part.So how to deal with the damage of the guide post during the use of the injection mold?

In several cases, the moving and fixed molds will produce huge lateral offset forces during injection.When the wall thickness of the plastic part is not uniform, the material flow passes through the thick wall at a high rate, and a greater pressure is generated here; the side of the plastic part is asymmetric, such as the mold with a stepped parting surface, and the opposite sides are reversed. The pressure is not equal.

Injection moldingMould factoryTo make a set of high-quality injection molds, you need to understand every detail in the design, manufacturing, and molding of each mold, and understand the purpose of each part in the mold.Knowing the important role of the guide post in the injection mold, and understanding the harm caused by the damage of the guide post to the entire mold, you will pay more attention to such problems in the subsequent use, and not only can better manufacture excellent plastic products. , It also greatly improves the service life of the injection mold.

Link to this article:What should I do if the guide post of the injection mold is damaged?