Plastic mold is a compact tool. It has a complicated shape and bears the expansion force of the blank. Therefore, there are high requirements for structural strength, rigidity, general hardness, general roughness and machining accuracy. The growth of plastic molds is the degree of mechanical manufacturing. One of the important signs. The cycle is very long and the processing cost is high (especially the manufacturing and processing costs of compact and complex plastic molds or large plastic molds are as high as hundreds of thousands or even millions of yuan).

After long-term operation, the plastic mold must be sharpened, and the sharpened blade must be demagnetized, and it cannot be magnetized, otherwise it will easily cause blockage. Plastic mold operating companies should keep detailed records, count their operations, maintenance (lubrication, cleaning, rust prevention) and damaged environments, and provide information based on damaged parts and components and the degree of wear for search and use. Solve the problem. Data and molding process parameters of plastic molds and materials used in products to shorten the trial run time of plastic molds and improve cross-production efficiency.

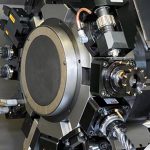

The combined plastic mold is formed by compression molding, extrusion molding, injection molding, blow molding and low foaming. The plastic mold mainly includes a cavity combined with the bottom plate of the concave mold, and a card board combined with the concave mold component and the concave mold. The concave mold is a convex mold with a variable core, which is composed of a convex mold combined base plate, a convex mold part, a convex mold combined card board, a cavity cutting part and a side cut combined board. Coordinated changes of mold convex, concave mold and auxiliary molding system. A series of plastic parts of different shapes and sizes can be processed. In the plastic processing industry, it is used in conjunction with plastic molding machines to provide complete configuration and precise size tools for plastic products. Due to the diversity of plastics and processing methods, as well as the complexity and simplicity of the structure of plastic molding machines and plastic products, the types and structures of plastic molds are also diverse.

Link to this article:What are the main uses of plastic mold processing